Common Draftbeer Questions

A: Draft beer is beer served directly from a keg rather than from a bottle or can. It's typically fresher and often preferred for its flavor and carbonation control.

Draft beer is stored and dispensed from a keg, offering better flavor preservation and less exposure to light and oxygen compared to bottled or canned beer.

A: While beer does not "go bad", it does change flavor with exposure to bacteria, oxygen, and temperature. The rate at which beer will spoil is dependent upon the combination of all three of these factors.

- If you dispense your beer with a party pump, which uses air instead of CO2 to drive the beer, you can only expect your beer to remain fresh for 8-12 hours.

- If you keep your kegs warm, and drive them with CO2 through a jockey box or other faucet, they will most likely last a couple of months.

- If you keep your beer cold, use CO2 instead of air to drive the beer, keep the dispensing system clean, and buy kegs from breweries that have strict sanitizing and cleaning procedures, your keg will last 4 months or more with minimal or no noticeable flavor change.

A: Depending on the type of keg, you can expect to get the following:

| Type | Gallons | Ounces | # of 12 oz. Beers | |

|---|---|---|---|---|

| 3 Gallon Keg | 3 | 384 | 32 |

| 5 Gallon Keg | 5 | 661 | 55 |

| Quarter Barrel Keg | 7.75 | 992 | 82 |

| Euro Keg | 13.2 | 1690 | 140 |

| Full-Size Keg (1/2 Barrel) | 15.5 | 1984 | 165 |

|  |

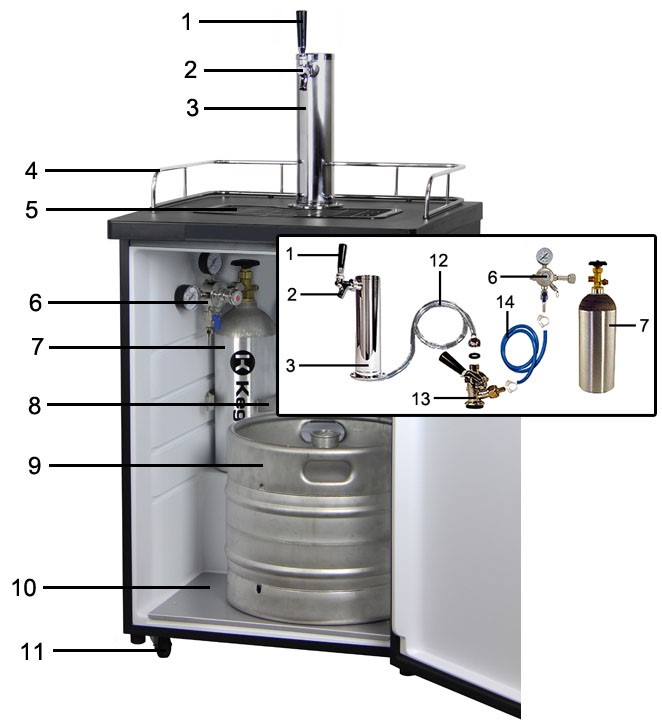

| Faucet Knob/Tap Handle | Push or pull the faucet handle to start beer flowing out of the faucet. |

| Faucet | Dispenses beer and controls its flow into your glass. Also referred to as a tap. |

| Draft Beer Tower | Contains the beer lines and holds the faucets in place. Can be air or glycol cooled, comes in various styles and finishes, and can hold single or multiple faucets. |

| Guard Rail | Helps prevent beer glasses from falling off of the kegerator. |

| Drip Tray | Located under the faucet to catch any runoff beer. |

| Regulator | Controls the flow of gas. |

| CO2 Tank | Houses the CO2 gas, which is used to push beer from the keg through the beer line to the faucet. |

| CO2 Tank Holder | Holds the CO2 tank in place on the kegerator. |

| Metal Keg Floor Support | Allows the kegerator floor to support the weight of a full keg, and prevents cool air from leaking out of the bottom of the unit. |

| Casters | Allows you to roll the kegerator wherever you need it. |

| Beer Line | Beer travels through the beer line from the keg coupler to the faucet. |

| Keg Coupler | Taps the keg, allowing gas into the keg and beer out of the keg. |

| Air Line | Allows CO2 to flow from the regulator into the keg, pushing beer out of the faucet. |

A: Temperature is a key factor in storing and dispensing draught beer. Beer can freeze at 28 degrees, and temperatures above 39 degrees cause the CO2 molecule to expand, making your beer foamy, so it is important to select and maintain proper operating temperatures inside the refrigerator cabinet. The optimum temperature for serving cold beer is between 34-38 degrees.

A: The ideal range is typically 10-14 PSI depending on the beer style and draft system setup. Incorrect pressure can cause foam or flat beer.

A: Keeping your glassware clean is the key to serving good draught beer. To achieve this:

- Maintain strict sanitary conditions in the glass washing area.

- Never wash glassware with utensils or dishes used to serve food. Food particles and/or residue can affect the quality/taste of draught beer.

- For best results, use a dedicated dishwasher for your glassware, or wash in a clean three-tub sink where you can clean the glass with hot water and detergent, rinse it in fresh cold water, and sanitize it with a mixture of hot water and the appropriate sanitizer.

- Do not use regular liquid household dish washing detergents for glassware. They are fat-based and will leave a slight oily film on the glass. This causes beer to go flat quickly. Use a detergent designed specifically for beer glass cleaning. It must be low-suds, odor-free, and non-fat.

- Avoid drying glassware with towels, as they tend to leave traces of lint on the surface of the glass. Instead, air-dry and store on a stainless-steel wire basket or corrugated basket or surface for maximum air circulation. Store in an odor, smoke, grease, and dust-free environment.

- We recommend that you use beer glassware only for beer. Dairy and other food products leave a residue which can affect the quality/taste of the draught.

- To perform the "sheeting test", dip a glass in water. If it has been properly cleaned, the glass will be evenly coated with water, which it will shed evenly in unbroken "sheets". If there is still film remaining, the water will break up into droplets.

- To perform the "salt test", sprinkle salt on the interior of a wet glass. The salt will adhere evenly to a clean surface, but will not adhere to any parts still containing film.

- To perform the "lacing test", fill a glass with beer. In a beer clean glass, foam will adhere to the inside of the glass in parallel rings after every sip, forming a lacing pattern. In an improperly cleaned glass, any foam will adhere in a loose, random pattern, if it adheres at all. A glass that has not been properly cleaned may have loose, large bubbles that will cause the head to disappear quickly.

A: Beer lines should be cleaned every two weeks with a cleaning solution. Dirty lines affect taste and can harbor bacteria.

Why Cleaning Beer Lines MattersKeeping your beer lines clean is essential for preserving the flavor and quality of your draft beer. Over time, beer stone (calcium oxalate), yeast, mold, and bacteria can accumulate inside the lines, leading to off-flavors, excessive foam, and even potential health risks. If you notice a sour taste or cloudy appearance in your beer, dirty lines are often to blame.

How Often and How to Clean Beer LinesFor best results, beer lines should be cleaned at least every two weeks using a professional-grade line cleaning solution. The process involves flushing the lines with the solution, rinsing thoroughly with water, and ensuring no residue remains. For systems that see heavy use, weekly cleanings may be necessary. Additionally, faucets, couplers, and other components should also be disassembled and sanitized regularly to maintain a clean and consistent pour.

Beverage Factory offering high quality beer line cleaning equipment that helps you to solve this problem.

A: Beer lines should be cleaned every two weeks with a cleaning solution. Dirty lines affect taste and can harbor bacteria.

Why Cleaning Beer Lines MattersKeeping your beer lines clean is essential for preserving the flavor and quality of your draft beer. Over time, beer stone (calcium oxalate), yeast, mold, and bacteria can accumulate inside the lines, leading to off-flavors, excessive foam, and even potential health risks. If you notice a sour taste or cloudy appearance in your beer, dirty lines are often to blame.

How Often and How to Clean Beer LinesFor best results, beer lines should be cleaned at least every two weeks using a professional-grade line cleaning solution. The process involves flushing the lines with the solution, rinsing thoroughly with water, and ensuring no residue remains. For systems that see heavy use, weekly cleanings may be necessary. Additionally, faucets, couplers, and other components should also be disassembled and sanitized regularly to maintain a clean and consistent pour.

Beverage Factory offering high quality beer line cleaning equipment that helps you to solve this problem.

- Make sure that your glass is "beer clean".

- Hold the glass about an inch under the faucet at a 45 degrees angle, then fully open the faucet. Make sure that the outside of the faucet does not touch the inside of the glass or the beer itself.

- Once the beer has reached about a halfway point in the glass, begin to gradually tilt the glass upright.

- Pour beer straight down into the glass, forming a one-inch collar of foam ("head").

- Quickly close the faucet to avoid overflow.

A: Growlers can be a great way to transport and share beer when a traditional keg is inconvenient. When filling a growler, be sure to always use clean and sanitized growlers and filling tubes, and be aware of how laws on filling growlers may vary in your state.

- Before filling a growler, it is always a good idea to rinse it out with cold water to cool down the growler and prevent the beer from excessively foaming.

- Insert a tube (3/8" ID x 1/2" OD works for standard faucets) into the faucet that reaches to the bottom of the growler.

- Open the faucet handle all the way and fill the growler from the bottom up.

- When foam begins to come out of the top of the growler, close the faucet, remove the tube, and seal the growler

Single Faucet Kegerator Beer Dispensers

Single Faucet Kegerator Beer Dispensers Dual Faucet Two Tap Kegerators

Dual Faucet Two Tap Kegerators Triple Faucet Three Tap Kegerators

Triple Faucet Three Tap Kegerators Undercounter Built-In Kegerators

Undercounter Built-In Kegerators Outdoor Kegerator Beer Dispensers

Outdoor Kegerator Beer Dispensers Commercial Kegerators

Commercial Kegerators Mini Kegerators

Mini Kegerators Cold Brew & Nitro Coffee Dispenser Kegerators

Cold Brew & Nitro Coffee Dispenser Kegerators Home Brew Kegerators

Home Brew Kegerators Carbonated Water Kegerators

Carbonated Water Kegerators 15" Kegerators

15" Kegerators Kombucha Equipment

Kombucha Equipment Guinness® Dispensing Kegerators

Guinness® Dispensing Kegerators Wine Kegerators

Wine Kegerators Kegerator Cabinets

Kegerator Cabinets Kegerator Covers and Accessories

Kegerator Covers and Accessories Kegerators

Kegerators Kegerator Conversion Kits

Kegerator Conversion Kits Kegs & Keg Accessories

Kegs & Keg Accessories Beer Faucets

Beer Faucets Beer Shanks

Beer Shanks Draft Beer Towers

Draft Beer Towers Keg Taps Couplers

Keg Taps Couplers Regulators & Gas Equipment

Regulators & Gas Equipment Beer & Gas Line Hose

Beer & Gas Line Hose Co2 and Nitrogen Air Tanks

Co2 and Nitrogen Air Tanks Beer Line Cleaning Equipment

Beer Line Cleaning Equipment Drip Trays

Drip Trays System Fittings

System Fittings Jockey Boxes

Jockey Boxes Keg Beer Party Pumps

Keg Beer Party Pumps Glassware

Glassware Guinness® Dispensing Equipment

Guinness® Dispensing Equipment Remote Glycol Systems

Remote Glycol Systems Wine Cooler Refrigerators

Wine Cooler Refrigerators Wine Cellar Cabinets

Wine Cellar Cabinets Wine Racks

Wine Racks Cooling Units

Cooling Units Wine Dispensing Systems

Wine Dispensing Systems Wine Accessories

Wine Accessories Wine Making

Wine Making Nitro Hot Draft System

Nitro Hot Draft System Ready to Drink Bag-in-a-Box Coffee Dispensing Equipment

Ready to Drink Bag-in-a-Box Coffee Dispensing Equipment Nitrogen Infusers

Nitrogen Infusers Nitrogen Tanks & Generators

Nitrogen Tanks & Generators Nitrogen Beer Regulators

Nitrogen Beer Regulators Nitro Cold Brew Coffee Kegs

Nitro Cold Brew Coffee Kegs Cold Brewed Coffee Tools

Cold Brewed Coffee Tools Cleaning Equipment

Cleaning Equipment Outdoor Appliances

Outdoor Appliances ADA Appliances

ADA Appliances Panel Ready Appliances

Panel Ready Appliances Commercial Grade Appliances

Commercial Grade Appliances Beverage Centers

Beverage Centers Refrigerators

Refrigerators Drawer Refrigerators

Drawer Refrigerators Ice Makers

Ice Makers Water Dispensers & Accessories

Water Dispensers & Accessories Freezers

Freezers Home Brew Equipment Kits

Home Brew Equipment Kits Fermentation Equipment

Fermentation Equipment Boiling and Mashing Equipment

Boiling and Mashing Equipment Home Brew Beer Kegs

Home Brew Beer Kegs Home Brew Kegerator Conversion Kits

Home Brew Kegerator Conversion Kits Brewing Tools

Brewing Tools Home Brew Ingredients

Home Brew Ingredients Cleaning Chemicals

Cleaning Chemicals Test Equipment

Test Equipment Home Brew Beer Bottles and Bottling Equipment

Home Brew Beer Bottles and Bottling Equipment Brewery Fittings

Brewery Fittings Draft Beer Equipment

Draft Beer Equipment Homebrewing Equipment

Homebrewing Equipment Wine Equipment

Wine Equipment Luxury Appliances and Refrigeration

Luxury Appliances and Refrigeration Coffee Equipment

Coffee Equipment Kombucha

Kombucha The Beverage Blog

The Beverage Blog Frequently Asked Beer Questions

Frequently Asked Beer Questions Shop by Brand

Shop by Brand Shop by Category

Shop by Category