Co2 Tank Frequently asked Questions

CO2 can be dangerous! Please use caution and always follow these steps:

- Always connect CO2 gas cylinder to reducing valve or regulator. Failure to do so could result in an explosion with possible death or injury when the cylinder valve is opened.

- Never connect gas cylinder directly to keg.

- Always secure gas cylinder in 'upright" position.

- Always keep gas cylinder away from heat.

- Never drop or throw CO2 gas cylinder.

- Always ventilate after CO2 leakage.

- Always check the D.O.T. (Department of Transport) test date located on the neck of the cylinder before installation. If over five (5) years, do not use, return the gas cylinder to gas supplier.

- Never connect a product container unless there are two (2) safety mechanisms in the pressure system.

- One at or on the CO2 regulator (the regulator supplied should be inclusive of such a safety mechanism).

- One at or on the product container coupler or in the pressure gas line (the keg coupler should be inclusive of such a safety mechanism).

- If it becomes difficult to breathe and your head starts to ache, abnormal concentrations of carbon dioxide may be present in the area. Close the main valve on the CO2 cylinder and leave the room immediately.

- Gas cylinders should be stored in the coolest part of the establishment, preferably at 70 degrees, and securely fastened in the upright position before the primary regulator is attached to the cylinder.

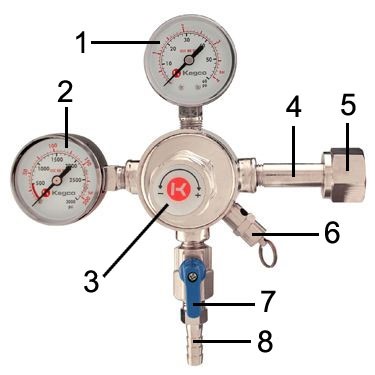

The main components of a regulator are:

- Low pressure gauge (reads the amount of internal keg pressure)

- High pressure gauge (indicates existing pressure in the CO2 cylinder)

- Pressure adjustment (before tapping the keg, screw clockwise until low pressure gauge indicates the desired pressure)

- CO2 inlet nipple

- CO2 inlet nut

- Pressure relief valve

- Optional shut-off valve

- Outlet fittings

For the standard 5 ft. run found in kegerators and most kegerator conversions, 10-12 PSI is recommended.

Longer draws in commercial establishments and jockey boxes require higher pressure depending on the distance the beer needs to travel. Once set, you should monitor the regulator to ensure the pressure remains constant at the desired level.

CO2 gauge pressure, temperature, and carbonation level reference chart

| Vol. Co2 | 2.1 | 2.2 | 2.3 | 2.4 | 2.5 | 2.6 | 2.7 | 2.8 | 2.9 | 3.0 | 3.1 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Temp. F | psi | psi | psi | psi | psi | psi | psi | psi | psi | psi | psi |

| 33 | 5.0 | 6.0 | 6.9 | 7.9 | 8.8 | 9.8 | 10.7 | 11.7 | 12.6 | 13.6 | 14.5 |

| 34 | 5.2 | 6.2 | 7.2 | 8.1 | 9.1 | 10.1 | 11.1 | 12.0 | 13.0 | 14.0 | 15.0 |

| 35 | 5.6 | 6.6 | 7.6 | 8.6 | 9.7 | 10.7 | 11.7 | 12.7 | 13.7 | 14.8 | 15.8 |

| 36 | 6.1 | 7.1 | 8.2 | 9.2 | 10.2 | 11.3 | 12.3 | 13.4 | 14.4 | 15.5 | 16.5 |

| 37 | 6.6 | 7.6 | 8.7 | 9.8 | 10.8 | 11.9 | 12.9 | 14.0 | 15.1 | 16.1 | 17.2 |

| 38 | 7.0 | 8.1 | 9.2 | 10.3 | 11.3 | 12.4 | 13.5 | 14.5 | 15.6 | 16.7 | 17.8 |

| 39 | 7.6 | 8.7 | 9.8 | 10.8 | 11.9 | 13.0 | 14.1 | 15.2 | 16.3 | 17.4 | 18.5 |

| 40 | 8.0 | 9.1 | 10.2 | 11.3 | 12.4 | 13.5 | 14.6 | 15.7 | 16.8 | 17.9 | 19.0 |

| 41 | 8.3 | 9.4 | 10.6 | 11.7 | 12.8 | 13.9 | 15.1 | 16.2 | 17.3 | 18.4 | 19.5 |

| 42 | 8.8 | 9.9 | 11.0 | 12.2 | 13.3 | 14.4 | 15.6 | 16.7 | 17.8 | 19.0 | 20.1 |

| Vol. Co2 | 2.1 | 2.2 | 2.3 | 2.4 |

|---|---|---|---|---|

| Temp. F | psi | psi | psi | psi |

| 33 | 5.0 | 6.0 | 6.9 | 7.9 |

| 34 | 5.2 | 6.2 | 7.2 | 8.1 |

| 35 | 5.6 | 6.6 | 7.6 | 8.6 |

| 36 | 6.1 | 7.1 | 8.2 | 9.2 |

| 37 | 6.6 | 7.6 | 8.7 | 9.8 |

| 38 | 7.0 | 8.1 | 9.2 | 10.3 |

| 39 | 7.6 | 8.7 | 9.8 | 10.8 |

| 40 | 8.0 | 9.1 | 10.2 | 11.3 |

| 41 | 8.3 | 9.4 | 10.6 | 11.7 |

| 42 | 8.8 | 9.9 | 11.0 | 12.2 |

| Vol. CO2 | 2.5 | 2.6 | 2.7 | 2.8 |

|---|---|---|---|---|

| Temp. F | psi | psi | psi | psi |

| 33 | 8.8 | 9.8 | 10.7 | 11.7 |

| 34 | 9.1 | 10.1 | 11.1 | 12 |

| 35 | 9.7 | 10.7 | 11.7 | 12.7 |

| 36 | 10.2 | 11.3 | 12.3 | 13.4 |

| 37 | 10.8 | 11.9 | 12.9 | 14 |

| 38 | 11.3 | 12.4 | 13.5 | 14.5 |

| 39 | 11.9 | 13 | 14.1 | 15.2 |

| 40 | 12.4 | 13.5 | 14.6 | 15.7 |

| 41 | 12.8 | 13.9 | 15.1 | 16.2 |

| 42 | 13.3 | 14.4 | 15.6 | 16.7 |

| Vol. CO2 | 2.9 | 3 | 3.1 |

|---|---|---|---|

| Temp. F | psi | psi | psi |

| 33 | 12.6 | 13.6 | 14.5 |

| 34 | 13 | 14 | 15 |

| 35 | 13.7 | 14.8 | 15.8 |

| 36 | 14.4 | 15.5 | 16.5 |

| 37 | 15.1 | 16.1 | 17.2 |

| 38 | 15.6 | 16.7 | 17.8 |

| 39 | 16.3 | 17.4 | 18.5 |

| 40 | 16.8 | 17.9 | 19 |

| 41 | 17.3 | 18.4 | 19.5 |

| 42 | 17.8 | 19 | 20.1 |

Based on Data form "Methods of Analysis", American Society of Brewing Chemists, 5th Edition

- To account for pressure loss when you are opening your faucet, you can add 1.5 psi

- The values in this table assume sea-level altitude, beer specific gravity of 1.015, and beer alcohol content at 3.8% abw or 4.8% abv. Values shown are in psig, or gauge pressure.

- It's important to remember that carbonation is proportional to absolute pressure, not gauge pressure. Atmospheric pressure drops as elevation goes up. Therefore, the gauge pressure needed to achieve proper carbonation at elevations above sea level must be increased. Add 1 psi for every 2,000 feet above sea level. For example, a retailer at sea level would use 11.3 psi gauge pressure to maintain 2.5 volumes of CO2 in beer served at 38F. That same retailer would need 13.3 psi gauge pressure at 4,000 feet elevation to maintain 2.5 volumes of CO2.

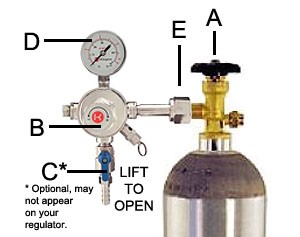

- Securely attach the regulator to the gas cylinder.

- Close the regulator's shut-off valve "C".

- Completely open the gas cylinder valve "A".

- Slowly turn the regulator adjustment "B" until the low pressure gauge "D" displays the desired pressure. Turn clockwise to increase the pressure, and counter-clockwise to decrease the pressure.

- Briefly pull the ring on the keg coupler's pressure relief valve "F" to allow the pressure already in the keg to vent

- Open the regulator shut-off valve "C" to allow gas to flow to the keg coupler.

- As the keg pressurizes, the needle on the low pressure gauge "D" will drop temporarily until the pressure has equalized, and then will return to the point you previously set it at.

- Briefly pull the ring on the keg coupler's pressure relief valve "F" again to allow gas to flow through the regulator to obtain a more accurate reading on the low pressure gauge "D".

- Re-check low pressure gauge "D" and use regulator adjustment "B" to readjust if necessary until the desired pressure is displayed.

If you will be dispensing multiple kegs that use the same CO2 pressure, you can split the gas flow to each keg using a two product regulator or an air line distributor. However, if you will be dispensing multiple kegs with different pressure requirements, secondary gas regulators will be needed to adjust the pressure for each keg.

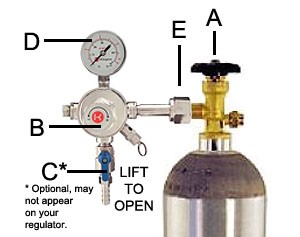

- Close valve by turning "A" clockwise

- Unscrew adjustment screw "B" (counter-clockwise) as far as it will go.

- Remove regulator from empty cylinder at "E".

- Remove dust cap from new cylinder at "E". Open and close valve "A" quickly to blow dust from the outlet.

- With cylinder valve "A" in closed position, reattach regulator to cylinder at "E". Be sure to include the CO2 washer.

- Open valve "A" all the way (this is important because the cylinder valve seals in two places).

- Readjust regulator pressure "B" and open optional valve "C".

Generally, no - refilling requires high-pressure equipment and is best left to professionals.

Some advanced users may refill using larger tanks, but this is not recommended without proper training and tools.

Many different types of businesses fill CO2 (carbon dioxide) tanks, often depending on the local demand, industry use, and licensing requirements.

- Industrial Gas Suppliers

- Examples: Airgas, Linde, Messer

- Use: Industrial-grade CO2 for welding, manufacturing, HVAC testing, etc.

- Tank Sizes: Typically large (5 lb to 100+ lb)

- Beverage Supply & Draft Equipment Companies

- Examples: BeverageFactory.com, Micro Matic, Kegco dealers

- Use: Food-grade CO2 for beer dispensing, soda fountains, kombucha, cold brew

- Tank Sizes: 2.5 lb to 20 lb cylinders

- Note: May also supply nitrogen and beer gas blends

- Fire Extinguisher Service Companies

- Paintball & Airsoft Shops

- Aquarium & Hydroponics Stores

- Homebrew Supply Stores

- Ice Cream & Soda Shops

- Mobile CO2 Refill Services (in some areas)

Important Tip:

Many industrial gas companies do not fill CO2 tanks onsite for walk-in customers. Instead, they may:

- Offer only tank exchanges (you trade your empty tank for a full one), or

- Send your tank out to be filled, which can take 1-2 business days or longer.

When calling or visiting, be sure to ask specifically:

- "Do you fill CO2 tanks onsite for walk-in customers?"

- Not just "Do you refill tanks?" this might mean an exchange or offsite service.

The size of CO2 tank you need depends on your beverage system, available space, and how often you want to refill it.

Here's a quick guide:

- 5 lb tank - Most popular for home kegerators. Dispenses approximately 6a1/2"8 full-size (half-barrel) kegs of beer or cold brew.

- 10 lb tank - Great for medium-use setups or small commercial systems. Lasts roughly twice as long as a 5 lb tank.

- 20 lb tank - Ideal for bars, cafes, or anyone dispensing large volumes. Requires less frequent refills.

- 2.5 lb or smaller - Perfect for portable or countertop systems, but will need frequent refilling.

It takes approximately 1/2 lb. of CO2 to dispense a 1/4 barrel of beer. Depending on what size keg you will be dispensing and what size CO2 tank you purchase, you can expect to dispense the following number of kegs:

| Keg | 2.5 lb. | 5 lb. | 10 lb. | 15 lb. | 20 lb. |

|---|---|---|---|---|---|

| 3 Gallon | 12-15 | 25-31 | 51-63 | 77-95 | 103-127 |

| 5 Gallon | 7-11 | 15-22 | 31-44 | 46-66 | 62-87 |

| 7.75 Gallon | 5-7 | 10-14 | 20-28 | 30-42 | 40-56 |

| 13.2 Gallon | 2-5 | 5-8 | 11-17 | 17-25 | 23-32 |

| 15.5 Gallon | 2-4 | 5-7 | 10-14 | 15-21 | 20-28 |

Yes, food-grade CO2 and industrial CO2 differ in terms of purity and intended use.

- Food-grade CO2(Grade E) is certified safe for consumption and meets specific purity standards set by the FDA. It is used for beverages like soda, beer, cold brew coffee, and sparkling water.

- Industrial CO2 may contain impurities such as oils or residues not safe for ingestion. It's typically used in manufacturing, welding, or other non-consumable applications.

Important: While both types may come from the same source, the handling, filtration, and certification process for food-grade CO2 ensures it's safe for use in food and drink systems.

Always request food-grade CO2 from your supplier if you're using it for beverage dispensing or anything consumed.

Proper storage of a CO2 tank is essential for safety and longevity.

Follow these best practices:

- Upright Position

- Always store CO2 tanks upright and secured to prevent tipping. This keeps the pressure regulator safe and ensures only gas (not liquid CO2) reaches your equipment.

- Cool, Dry, and Well-Ventilated Area

- Store tanks in a cool (ideally below 125°F), dry, and well-ventilated location.

- Avoid direct sunlight, heaters, or confined spaces where gas could accumulate in the event of a leak.

- Keep Away from Flames or Sparks

- CO2 is not flammable, but high-pressure tanks should be kept away from open flames or electrical sparks for general safety.

- Cap It When Not in Use

- If the tank is disconnected or in long-term storage, keep the valve cap or protective plug on to protect the valve stem.

CONNECT WITH US!

@BeverageFactoryAdded to Cart

.....

Single Faucet Kegerator Beer Dispensers

Single Faucet Kegerator Beer Dispensers Dual Faucet Two Tap Kegerators

Dual Faucet Two Tap Kegerators Triple Faucet Three Tap Kegerators

Triple Faucet Three Tap Kegerators Undercounter Built-In Kegerators

Undercounter Built-In Kegerators Outdoor Kegerator Beer Dispensers

Outdoor Kegerator Beer Dispensers Commercial Kegerators

Commercial Kegerators Mini Kegerators

Mini Kegerators Cold Brew & Nitro Coffee Dispenser Kegerators

Cold Brew & Nitro Coffee Dispenser Kegerators Home Brew Kegerators

Home Brew Kegerators Carbonated Water Kegerators

Carbonated Water Kegerators 15" Kegerators

15" Kegerators Kombucha Equipment

Kombucha Equipment Guinness® Dispensing Kegerators

Guinness® Dispensing Kegerators Wine Kegerators

Wine Kegerators Kegerator Cabinets

Kegerator Cabinets Kegerator Covers and Accessories

Kegerator Covers and Accessories Kegerators

Kegerators Kegerator Conversion Kits

Kegerator Conversion Kits Kegs & Keg Accessories

Kegs & Keg Accessories Beer Faucets

Beer Faucets Beer Shanks

Beer Shanks Draft Beer Towers

Draft Beer Towers Keg Taps Couplers

Keg Taps Couplers Regulators & Gas Equipment

Regulators & Gas Equipment Beer & Gas Line Hose

Beer & Gas Line Hose Co2 and Nitrogen Air Tanks

Co2 and Nitrogen Air Tanks Beer Line Cleaning Equipment

Beer Line Cleaning Equipment Drip Trays

Drip Trays System Fittings

System Fittings Jockey Boxes

Jockey Boxes Keg Beer Party Pumps

Keg Beer Party Pumps Glassware

Glassware Guinness® Dispensing Equipment

Guinness® Dispensing Equipment Remote Glycol Systems

Remote Glycol Systems Wine Cooler Refrigerators

Wine Cooler Refrigerators Wine Cellar Cabinets

Wine Cellar Cabinets Wine Racks

Wine Racks Cooling Units

Cooling Units Wine Dispensing Systems

Wine Dispensing Systems Wine Accessories

Wine Accessories Wine Making

Wine Making Nitro Hot Draft System

Nitro Hot Draft System Ready to Drink Bag-in-a-Box Coffee Dispensing Equipment

Ready to Drink Bag-in-a-Box Coffee Dispensing Equipment Nitrogen Infusers

Nitrogen Infusers Nitrogen Tanks & Generators

Nitrogen Tanks & Generators Nitrogen Beer Regulators

Nitrogen Beer Regulators Nitro Cold Brew Coffee Kegs

Nitro Cold Brew Coffee Kegs Cold Brewed Coffee Tools

Cold Brewed Coffee Tools Cleaning Equipment

Cleaning Equipment Outdoor Appliances

Outdoor Appliances ADA Appliances

ADA Appliances Panel Ready Appliances

Panel Ready Appliances Commercial Grade Appliances

Commercial Grade Appliances Beverage Centers

Beverage Centers Refrigerators

Refrigerators Drawer Refrigerators

Drawer Refrigerators Ice Makers

Ice Makers Water Dispensers & Accessories

Water Dispensers & Accessories Freezers

Freezers Home Brew Equipment Kits

Home Brew Equipment Kits Fermentation Equipment

Fermentation Equipment Boiling and Mashing Equipment

Boiling and Mashing Equipment Home Brew Beer Kegs

Home Brew Beer Kegs Home Brew Kegerator Conversion Kits

Home Brew Kegerator Conversion Kits Brewing Tools

Brewing Tools Home Brew Ingredients

Home Brew Ingredients Cleaning Chemicals

Cleaning Chemicals Test Equipment

Test Equipment Home Brew Beer Bottles and Bottling Equipment

Home Brew Beer Bottles and Bottling Equipment Brewery Fittings

Brewery Fittings Draft Beer Equipment

Draft Beer Equipment Homebrewing Equipment

Homebrewing Equipment Wine Equipment

Wine Equipment Luxury Appliances and Refrigeration

Luxury Appliances and Refrigeration Coffee Equipment

Coffee Equipment Kombucha

Kombucha The Beverage Blog

The Beverage Blog Frequently Asked Beer Questions

Frequently Asked Beer Questions Shop by Brand

Shop by Brand Shop by Category

Shop by Category