November 03, 2017

Cask-conditioned beer, also known as Real Ale, is beer that has gone through a second fermentation process, is unpasteurized and served from a cask keg with no added nitrogen or CO2. Instead, co2 builds up naturally in the cask during fermentation. Once it is fermented, it is then served straight from the cask. This gives it a distinct and incredibly fresh taste that has a much gentler level of carbonation and usually features a bit more complex flavor and aromatic profile. Cask kegs are best enjoyed over a day or two and are not intended for long term storage. They are ideal for local tastings and popular cask nights where they are expected to be emptied in one evening. In order to begin the brewing process, you will need a few different tools.

Cask

A cask, also known as a firkin (10.8 gallons) or a pin (5.4 gallons), is a traditionally barrel shaped container that stores and ferments beer. It has a 2 inch hole on the side for the shive (plug), and a one inch hole at the end for the keystone (where you tap the beer). Casks date back to the Iron Age, when the Celts developed wooden barrels with iron hoops to store goods. Over the years, this developed into a method of preserving and storing beer. A cask can be made of plastic or wood but typically it is made of stainless steel. This is the most important part of cask brewing, so if you need a cask, click here

Spile

A spile is basically a small wooden peg that is nailed into the shive to stop the keg or "air" the keg. A hard spile is inserted into the keg after the conditioning process has ended in order to maintain carbonation levels. Once the beer is tapped the soft spile replaces the hard spile. A soft spile is inserted in order to release excess CO2. This allows for equalization prior to serving. Beverage factory offers both hard and soft spiles here.

Spigot

This is the spout that is pounded into the keystone using a mallet in order to tap the beer. The beer then lets gravity take over to get the beer flowing. If you ever want to get the beer out of your cask, we have spigots available here.

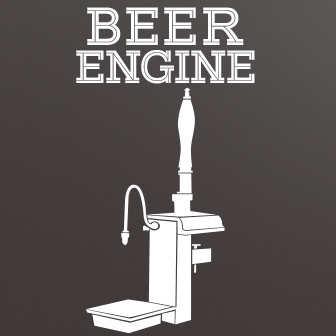

Beer engine

If you want to get fancy, you can pump directly from the cask using a beer engine. This directly draws up beer from the cask through a beer line. A cask ale hand pump is normally manually operated, but can also be gas or electrically operated. They normally hide under the bar counter with the handles sticking up. Most beer engines include a sparkler. This attaches to the nozzle and acts like a showerhead. When beer pours from it, it froths the beer and gives it a nice head. Beer engines are available for purchase here.

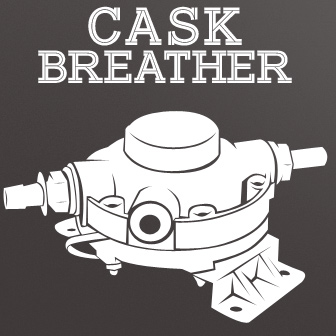

Cask Breather

The trouble with Cask brewing is sometimes you can't finish a whole cask of beer in 2 days before it spoils. A cask breather replaces head space with CO2 at atmospheric pressure, allowing you to extend the life of your cask ale. If you don't think you can finish a whole cask of beer within 2 days, cask breathers are available with our other cask ale supplies here.

Stillage

The cask needs to stay absolutely still during the clearing process. During this process yeast and finings start sticking to the inside of the keg. If the keg is not kept absolutely still, it will dislodge this sediment from the sides of the cask and go into the beer. This clouds the beer and as every brewer knows, cask beer is not supposed to be cloudy. This is where the stillage comes in. A stillage keeps the cask keg still and is also angled to make pouring and dispensing easier. This is incredibly important in the cask keg dispensing and brewing process. If you need a stillage they are available right here.

Single Faucet Kegerator Beer Dispensers

Single Faucet Kegerator Beer Dispensers Dual Faucet Two Tap Kegerators

Dual Faucet Two Tap Kegerators Triple Faucet Three Tap Kegerators

Triple Faucet Three Tap Kegerators Undercounter Built-In Kegerators

Undercounter Built-In Kegerators Outdoor Kegerator Beer Dispensers

Outdoor Kegerator Beer Dispensers Commercial Kegerators

Commercial Kegerators Mini Kegerators

Mini Kegerators Cold Brew & Nitro Coffee Dispenser Kegerators

Cold Brew & Nitro Coffee Dispenser Kegerators Carbonated Water Kegerators

Carbonated Water Kegerators Home Brew Kegerators

Home Brew Kegerators 15" Kegerators

15" Kegerators Kombucha Equipment

Kombucha Equipment Guinness® Dispensing Kegerators

Guinness® Dispensing Kegerators Vending Kegerators

Vending Kegerators Wine Kegerators

Wine Kegerators Kegerator Cabinets

Kegerator Cabinets Kegerator Covers and Accessories

Kegerator Covers and Accessories Kegerators

Kegerators Kegerator Conversion Kits

Kegerator Conversion Kits Kegs & Keg Accessories

Kegs & Keg Accessories Beer Faucets

Beer Faucets Beer Shanks

Beer Shanks Draft Beer Towers

Draft Beer Towers Keg Taps Couplers

Keg Taps Couplers Regulators & Gas Equipment

Regulators & Gas Equipment Beer & Gas Line Hose

Beer & Gas Line Hose Co2 and Nitrogen Air Tanks

Co2 and Nitrogen Air Tanks Beer Line Cleaning Equipment

Beer Line Cleaning Equipment Drip Trays

Drip Trays System Fittings

System Fittings Jockey Boxes

Jockey Boxes Keg Beer Party Pumps

Keg Beer Party Pumps Glassware & Accessories

Glassware & Accessories Guinness® Dispensing Equipment

Guinness® Dispensing Equipment Remote Glycol Systems

Remote Glycol Systems Wine Cooler Refrigerators

Wine Cooler Refrigerators Wine Cellar Cabinets

Wine Cellar Cabinets Wine Racks

Wine Racks Cooling Units

Cooling Units Wine Dispensing Systems

Wine Dispensing Systems Wine Glasses

Wine Glasses Wine Accessories

Wine Accessories Howard Miller Wine & Spirits Furniture

Howard Miller Wine & Spirits Furniture Wine Making

Wine Making Nitro Hot Draft System

Nitro Hot Draft System Ready to Drink Bag-in-a-Box Coffee Dispensing Equipment

Ready to Drink Bag-in-a-Box Coffee Dispensing Equipment Nitrogen Infusers

Nitrogen Infusers Nitrogen Tanks & Generators

Nitrogen Tanks & Generators Nitrogen Beer Regulators

Nitrogen Beer Regulators Nitro Cold Brew Coffee Kegs

Nitro Cold Brew Coffee Kegs Cold Brewed Coffee Tools

Cold Brewed Coffee Tools Espresso Machines

Espresso Machines Cleaning Equipment

Cleaning Equipment Outdoor Appliances

Outdoor Appliances ADA Appliances

ADA Appliances Panel Ready Appliances

Panel Ready Appliances Commercial Grade Appliances

Commercial Grade Appliances Beverage Centers

Beverage Centers Refrigerators

Refrigerators Drawer Refrigerators

Drawer Refrigerators Ice Makers

Ice Makers Water Dispensers & Accessories

Water Dispensers & Accessories Freezers

Freezers Home Brew Equipment Kits

Home Brew Equipment Kits Fermentation Equipment

Fermentation Equipment Boiling and Mashing Equipment

Boiling and Mashing Equipment Home Brew Beer Kegs

Home Brew Beer Kegs Home Brew Kegerator Conversion Kits

Home Brew Kegerator Conversion Kits Brewing Tools

Brewing Tools Home Brew Ingredients

Home Brew Ingredients Cleaning Chemicals

Cleaning Chemicals Test Equipment

Test Equipment Home Brew Beer Bottles and Bottling Equipment

Home Brew Beer Bottles and Bottling Equipment Brewery Fittings

Brewery Fittings Draft Beer Equipment

Draft Beer Equipment Homebrewing Equipment

Homebrewing Equipment Wine Equipment

Wine Equipment Luxury Appliances and Refrigeration

Luxury Appliances and Refrigeration Coffee Equipment

Coffee Equipment Home Bar & Barware

Home Bar & Barware Kombucha

Kombucha The Beverage Blog

The Beverage Blog Frequently Asked Beer Questions

Frequently Asked Beer Questions Shop by Brand

Shop by Brand Shop by Category

Shop by Category