In an article on BYO Fermentation Time Line, Chris White, the president of White Labs Yeast Company, says:

"Professional breweries cool the contents of the fermenter gradually to 35° to 40° F, which forces most of the yeast to flocculate. Most home brewers do not have the facilities to do this, so they must wait for the fermenter to clear."

https://byo.com/stories/issue/item/635-fermentation-time-line

Brew like the Pros!

It no longer takes the resources of a professional brewer or the knowledge of an electrical engineer to take control of your fermentation schedule. With current technology, home brewers can now take control of the brewing process like a pro. Using a thermostat power control unit plugged into a freezer, or a kegerator with a digital read out and adjustable thermostat, you can take control of your fermentation schedule to produce clean ales, lagers or even complex beers with dynamic fermentation schedules.

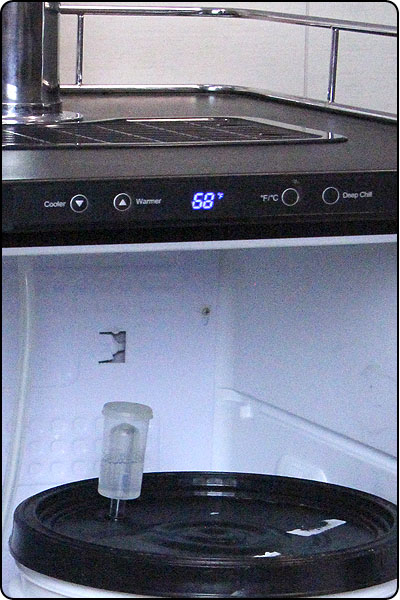

A thermostat power control unit overrides an appliance's thermostat, regulating the amount of energy getting to the appliance and allowing you precise control over the temperature settings and the amount of temperature fluctuation between cooling cycles. The same concept can be used in affordable kegerators such as Kegco's K309 models. With a digital thermometer and push-button controls, the days of guessing what temperature you will get by setting a dial to 5 are over.

To give an example of how I use this technology, I recently put a five-gallon batch in a Kegco K309 kegerator for the duration of the fermentation schedule. It was a stout recipe that I have brewed a few times previously with great results. Living in San Diego, I don't have to deal with extreme temperature variations, but this past January I lost 15 gallons of pale ale due to unseasonably warm spells. I had 3 buckets that were 2 days into fermentation when they saw temperatures in the high 80's. By the time I saw the thermometer, it was 81° F. When the beer finished, it was full of unwanted esters which gave it Belgian taste.

My expectations for this batch were very high because instead of throwing a bucket/carboy in the corner, I was able to control the fermentation temperature accurately through the entire process with a kegerator.

Brewing Process

We pitched WL001 at a precisely measured 75° F and then quickly brought the temperature down to 68° F, where it stayed for 10 days. I then raised the temperature to 74° F for diacetyl rest before bringing it down to 50° F for two days. I dropped it down to 35° F for a final crash before racking it into a secondary at 35° F for a couple days until I could keg and carbonate.

The finished product did not disappoint, as it was 7.7% ABV, malty and delicious. I can't say it was noticeably better than previous batches, but it was definitely a clean stout and eliminating the chance of getting off tastes from unpredictable fermenting temps allowed me to rest easy throughout the process.

Summary

Controlling your fermentation ensures a more consistent final product and you eliminate the chance of losing a batch to unpredictable weather. It gives you one more variable to control in your homebrew process and it is a very simple to do with the right tools.

Anthony B.

Product Manager / Resident Brewer

Beverage Factory

Single Faucet Kegerator Beer Dispensers

Single Faucet Kegerator Beer Dispensers Dual Faucet Two Tap Kegerators

Dual Faucet Two Tap Kegerators Triple Faucet Three Tap Kegerators

Triple Faucet Three Tap Kegerators Undercounter Built-In Kegerators

Undercounter Built-In Kegerators Outdoor Kegerator Beer Dispensers

Outdoor Kegerator Beer Dispensers Commercial Kegerators

Commercial Kegerators Mini Kegerators

Mini Kegerators Cold Brew & Nitro Coffee Dispenser Kegerators

Cold Brew & Nitro Coffee Dispenser Kegerators Carbonated Water Kegerators

Carbonated Water Kegerators Home Brew Kegerators

Home Brew Kegerators 15" Kegerators

15" Kegerators Kombucha Equipment

Kombucha Equipment Guinness® Dispensing Kegerators

Guinness® Dispensing Kegerators Vending Kegerators

Vending Kegerators Wine Kegerators

Wine Kegerators Kegerator Cabinets

Kegerator Cabinets Kegerator Covers and Accessories

Kegerator Covers and Accessories Kegerators

Kegerators Kegerator Conversion Kits

Kegerator Conversion Kits Kegs & Keg Accessories

Kegs & Keg Accessories Beer Faucets

Beer Faucets Beer Shanks

Beer Shanks Draft Beer Towers

Draft Beer Towers Keg Taps Couplers

Keg Taps Couplers Regulators & Gas Equipment

Regulators & Gas Equipment Beer & Gas Line Hose

Beer & Gas Line Hose Co2 and Nitrogen Air Tanks

Co2 and Nitrogen Air Tanks Beer Line Cleaning Equipment

Beer Line Cleaning Equipment Drip Trays

Drip Trays System Fittings

System Fittings Jockey Boxes

Jockey Boxes Keg Beer Party Pumps

Keg Beer Party Pumps Glassware & Accessories

Glassware & Accessories Guinness® Dispensing Equipment

Guinness® Dispensing Equipment Remote Glycol Systems

Remote Glycol Systems Wine Cooler Refrigerators

Wine Cooler Refrigerators Wine Cellar Cabinets

Wine Cellar Cabinets Wine Racks

Wine Racks Cooling Units

Cooling Units Wine Dispensing Systems

Wine Dispensing Systems Wine Glasses

Wine Glasses Wine Accessories

Wine Accessories Howard Miller Wine & Spirits Furniture

Howard Miller Wine & Spirits Furniture Wine Making

Wine Making Nitro Hot Draft System

Nitro Hot Draft System Ready to Drink Bag-in-a-Box Coffee Dispensing Equipment

Ready to Drink Bag-in-a-Box Coffee Dispensing Equipment Nitrogen Infusers

Nitrogen Infusers Nitrogen Tanks & Generators

Nitrogen Tanks & Generators Nitrogen Beer Regulators

Nitrogen Beer Regulators Nitro Cold Brew Coffee Kegs

Nitro Cold Brew Coffee Kegs Cold Brewed Coffee Tools

Cold Brewed Coffee Tools Espresso Machines

Espresso Machines Cleaning Equipment

Cleaning Equipment Outdoor Appliances

Outdoor Appliances ADA Appliances

ADA Appliances Panel Ready Appliances

Panel Ready Appliances Commercial Grade Appliances

Commercial Grade Appliances Beverage Centers

Beverage Centers Refrigerators

Refrigerators Drawer Refrigerators

Drawer Refrigerators Ice Makers

Ice Makers Water Dispensers & Accessories

Water Dispensers & Accessories Freezers

Freezers Home Brew Equipment Kits

Home Brew Equipment Kits Fermentation Equipment

Fermentation Equipment Boiling and Mashing Equipment

Boiling and Mashing Equipment Home Brew Beer Kegs

Home Brew Beer Kegs Home Brew Kegerator Conversion Kits

Home Brew Kegerator Conversion Kits Brewing Tools

Brewing Tools Home Brew Ingredients

Home Brew Ingredients Cleaning Chemicals

Cleaning Chemicals Test Equipment

Test Equipment Home Brew Beer Bottles and Bottling Equipment

Home Brew Beer Bottles and Bottling Equipment Brewery Fittings

Brewery Fittings Draft Beer Equipment

Draft Beer Equipment Homebrewing Equipment

Homebrewing Equipment Wine Equipment

Wine Equipment Luxury Appliances and Refrigeration

Luxury Appliances and Refrigeration Coffee Equipment

Coffee Equipment Home Bar & Barware

Home Bar & Barware Kombucha

Kombucha The Beverage Blog

The Beverage Blog Frequently Asked Beer Questions

Frequently Asked Beer Questions Shop by Brand

Shop by Brand Shop by Category

Shop by Category